Rotomolding Progress

-

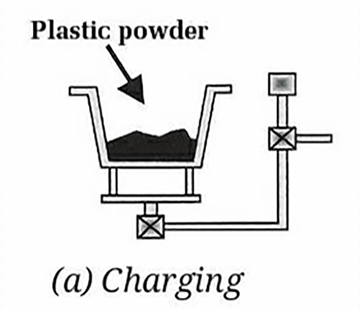

Plastic raw material (typically in powder form) is placed inside a mold (cast aluminum, CNC machined aluminum)

-

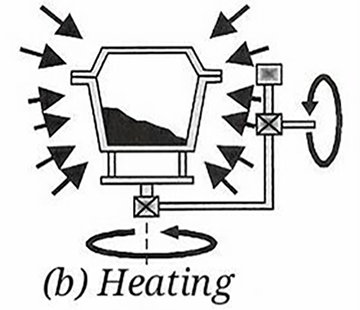

The mold is attached to an arm of a rotational molding machine, and enters the oven where it rotates (rotational molding) on two axes.

-

As the plastic material melts, it begins to adhere to the inside mold walls, building wall thickness and taking on the shape and texture of the interior mold surface.

-

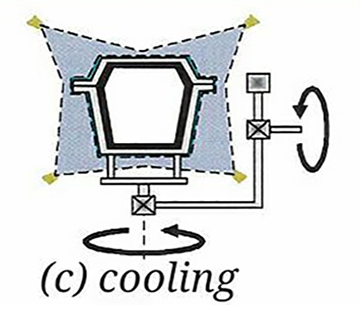

After rotating in the oven, the mold enters the cooling phase, where the molten material eventually solidifies into the finished, hollow plastic part.

-

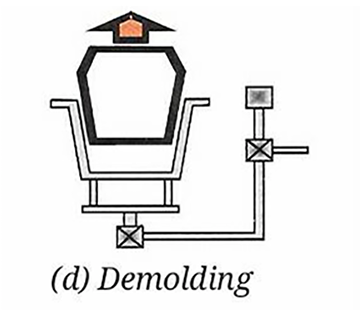

The part is then removed from the mold, where it undergoes a variety of secondary operations (trimming, foam-filling, assembly, etc.) prior to shipment.

Top